Miniload System

Miniload

stacker is mainly used in AS/RS. The storage units are usually as bins,

with high dynamic values, advanced and energy-saving drive technology,

which enables the customer's small parts warehouse to achieve higher

flexibility.

With

the continuous increase of labor costs and land use costs, the market's

demand for labor-saving and high-efficiency warehousing systems becomes

more and more, and the attention of goods-to-person system becomes more

and more as well. The birth of Miniload system provides an effective

solution for quick dismantling and sorting.

Miniload system advantages:

1. High work efficiency

The

maximum running speed of the Miniload stacker in this project can reach

120m/min, which can finish inbound and outbound in short time;

2. Increase warehouse utilization

The Miniload stacker is small and can operate in a narrow lane. It is also suitable for high-rise racking operations and greatly increases warehouse utilization;

3. High grade of automation

The

Miniload system can be controlled remotely, no manual intervention is

required in the operation process. It is high grade of automation, can

realize efficient management.

4. Good stability

Miniload system has high reliability and stability.

Introduction

NANJING

INFORM STORAGE EQUIPMENT (GROUP) CO.,LTD provides a well-known

automobile company with an efficient miniload system solution. This

solution is suitable for fast dismantling and picking of multiple SKUs.

It has the advantages of high operation efficiency and high warehouse

utilization.

Overview

The

project adopts Miniload storage system with a height of nearly 8

meters. The overall plan is 2 lanes, 2 Miniload stackers, 1 WCS+WMS

system, and 1 cargo-to-person conveying system. There are more than

3,000 cargo spaces in total, and the system's operating capacity: 50

bins/hour for a lane.

Project Advantages and Emergency Failure Solutions

Advantage:

1. There are many types of SKUs to achieve precise selection

This

automobile spare parts warehouse has a wide variety of SKUs, by WMS

system, it greatly improves the efficiency and accuracy of order

processing;

2. Can be outbound directly at random

This

project has relatively high requirements for outbound. The single-deep

miniload system solution can realize the function of random outbound,

which greatly reduces the response time.

3. Human and machine are isolated

Physically

isolate operating equipment from people through isolation mesh, safety

door locks and other equipment, to ensure the safety of people and

equipment.

Emergency fault solution:

1. Equipped with a generator room, equipment will not shut down when an emergency power failure occurs in the warehouse;

2. Equipped with a picking station. When equipment can't go out of warehouse normally, manual picking can be done through picking station to meet the normal supply of spare parts.

INFORM

Miniload system solution successfully assisted the auto company in

upgrading its automatic storage system, solving problems such as tight

storage area and low warehousing efficiency for customers, and improving

market competitiveness. INFORM is committed to providing good solutions

for enterprises and factories!

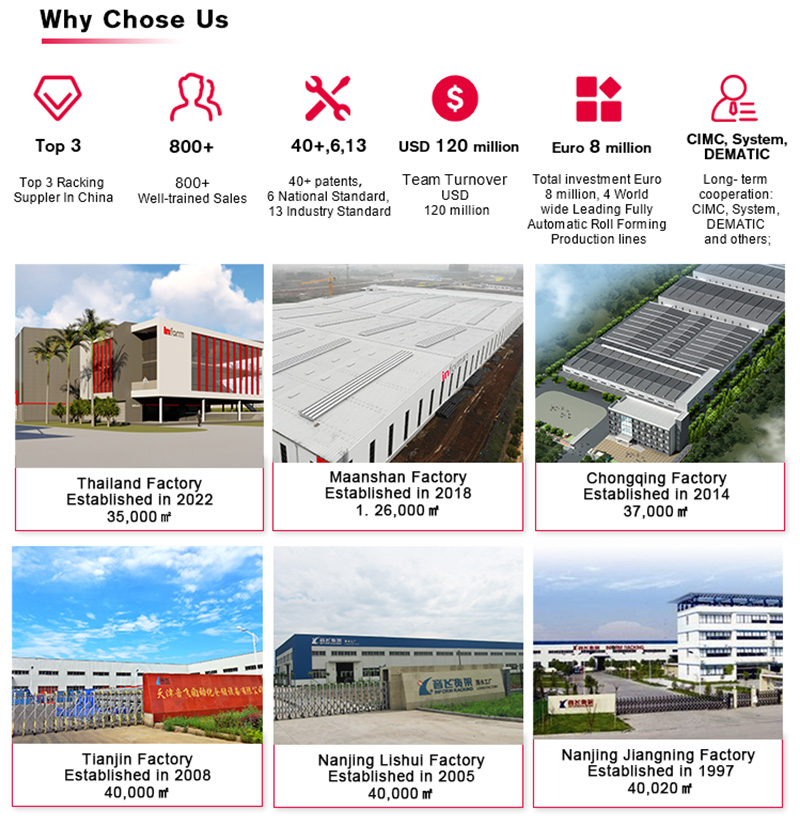

Why choose us?

Top 3 Racking Suppler In China

The Only One A-share Listed Racking Manufacturer

1. NanJing Inform Storage Equipment Group,as a public listed state controlled enterprise, specialized in the logistic storage solution field since 1997.( 27 years of experience)

2.Core Business: Racking

Strategic Business:Automatic System Integration

Growing Business: Warehouse Operation Service

3.Inform owns 6 factories, with over 1000 employees. Inform listed A-share on June 11, 2015, stock code: 603066, becoming the first listed company in China’s warehousing industry

Q1: What’s your trading terms?

1) Payment terms: As general, T/T 30% deposit after order confirmed, 70% balance paid against BL. L/C also available.

2) Shipping port: Shanghai / Nanjing port China.

3) Discounts: we will offer the biggest discount for large quantity.

Q2: Are you a factory or trading company?

A:We are factory and have 5 factories.We’ve been in the market of logistic storage solutionssince 1997.We design,manufacture racking and assemble shuttle, four-way shuttle etc by ourselves.

Q3: Do you have OEM products to sell?

A:Yes.Both OEM and ODM are available .

Q4:Do you have the minimum order requirements?

A:Any quantity and customized design is acceptable.

Q5:Are samples available?

A:Yes. Short sections of samples can be provided for free, but the international transportation will be at the customers’ expense.

Q6:What’s the delivery time?

A:It depends on the order quantity and racking types. Generally speaking, for the standard pallet racking, it will be within 20 days.