Short Description:

1. Drive in, as its name, requires forklift drives

inside of racking to operate pallets. With the help of guide rail,

forklift is able to move freely inside of racking.

2. Drive in is a cost-effective solution to high-density storage, which enables the highest use of available space.

Product Details

Racking Components:

Product Analysis:

Racking type: | Drive in racking |

Material: | Q235/Q355 Steel | Certificate | CE, ISO |

Size: | customized | Loading: | 500-1500kg/pallet |

Surface treatment: | powder coating/galvanized | Color: | RAL color code |

Pitch | 75mm | Place of origin | Nanjing, China |

Application: | big batch and less variety cargos, like food, tobacco and freezer. |

① High utilization of warehouse space

Compared with selective pallet rack, drive in utilizes 80% of storage space by eliminating aisles, making warehouse space utilization rate increasing by 40%.

② Adjustable storage height and depth

Drive in racking can be set up to 8 pallets depth and 10m high. But the most recommended design is 4-5 pallets depth and 4 levels high for safe loading/unloading and convenient management.

③ Cold room

Due to the high density that drive in racking system provide, it is ideal for storage at low temperature in cold room. Since coolers and freezers are expensive property, getting the most storage capacity and highest efficiency are priority. It is an excellent solution for cold room storage.

④ Drive in and Drive through

Drive in racking is FILO(first in last out) racking type, requiring loading and retrieving from the same side. It can be extended to another structure—Drive through racking.

Drive through can realize FIFO(first in first out) purpose by removing back bracing, so loading is from one side and unloading is from the other. The advantage is that storage capacity is increased again, while the disadvantage is that racking stability is reduced without back bracing.

Project cases:

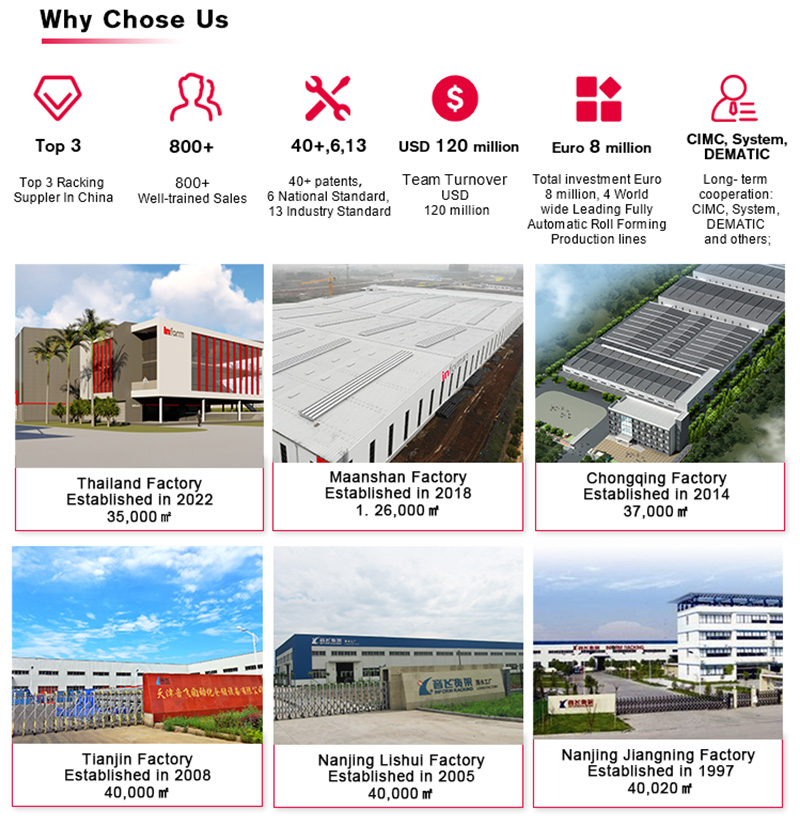

Why choose us?

Top 3 Racking Suppler In China

The Only One A-share Listed Racking Manufacturer

1. NanJing Inform Storage Equipment Group,as a public listed state controlled enterprise, specialized in the logistic storage solution field since 1997.( 27 years of experience)

2.Core Business: Racking

Strategic Business:Automatic System Integration

Growing Business: Warehouse Operation Service

3.Inform owns 6 factories, with over 1000 employees. Inform listed A-share on June 11, 2015, stock code: 603066, becoming the first listed company in China’s warehousing industry.

Q1: What’s your trading terms?

1) Payment terms: As general, T/T 30% deposit after order confirmed, 70% balance paid against BL. L/C also available.

2) Shipping port: Shanghai / Nanjing port China.

3) Discounts: we will offer the biggest discount for large quantity.

Q2: Are you a factory or trading company?

A:We are factory and have 5 factories.We’ve been in the market of logistic storage solutionssince 1997.We design,manufacture racking and assemble shuttle, four-way shuttle etc by ourselves.

Q3: Do you have OEM products to sell?

A:Yes.Both OEM and ODM are available .

Q4:Do you have the minimum order requirements?

A:Any quantity and customized design is acceptable.

Q5:Are samples available?

A:Yes. Short sections of samples can be provided for free, but the international transportation will be at the customers’ expense.

Q6:What’s the delivery time?

A:It depends on the order quantity and racking types. Generally speaking, for the standard pallet racking, it will be within 20 days.