With the diversification and complexity of the business types of logistics centers, the heavy duty four-way shuttle as a new automated storage technology gradually enters people's vision. As a technical upgrade of the two-way shuttle car system, the pallet type four-way shuttle car system can drive in multiple directions, cross the roadway efficiently and flexibly, without space restrictions. In the past two years, more and more four-way shuttle projects have been successfully applied.

Recently, Nanjing Inform Group, as a partner, has optimized the design together with Dowell company. Through innovative application of the heavy duty four-way shuttle system, it has provided technical guarantee for the efficient operation of the entire logistics system.

Sichuan Dowell Science & Technology, Inc. was established in November 2003. Its main business is the R & D, production and sales of fine chemicals. The products cover leather chemicals, water-based color pastes, industrial coating materials, adhesives, etc. The production capacity of more than 200. Dowell company was listed on GEM in 2016. In recent years, the company has maintained a leading position in the domestic leather chemical industry and is committed to serving the leather industry while vigorously developing the smart equipment industry and laying out the industry 4.0 era.

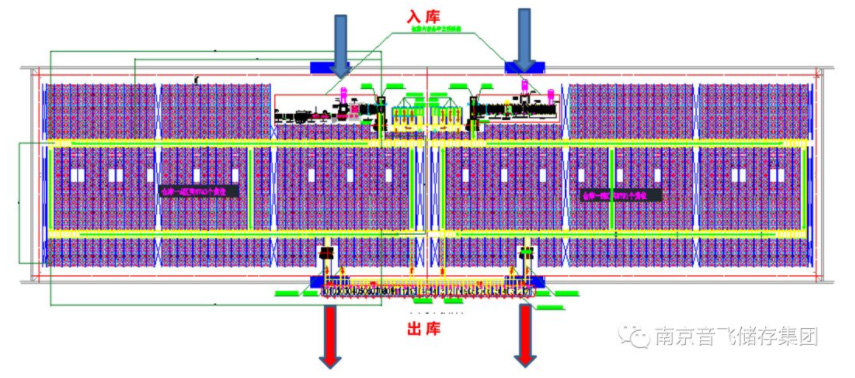

The project is located in Xinjin County, Chengdu, and civil engineering construction began in early 2018. The warehouse was officially put into use in November 2019. The maximum storage capacity of the intensive storage system reaches more than 7600 tons, the planned daily throughput capacity is 100 ~ 120 tons, total of 7534 pallet positions, of which 1876 stores a total of 1876 tons of barrels, powder, empty trays, and remaining materials 5,658 storage positions in the second, third and fourth levels.

The whole project serves Dawei Xinjin new factory. In the same year, the Chengdu Municipal Government and various units in the leather chemical industry organized personnel to visit and guide the project.

In order to solve the customer's assumption that the warehouse will be connected to the left and right warehouses to improve utilization and access efficiency. Before the warehouse established , there is an idea of introducing mechanized and automated logistics technology equipment . The high flexibility of the heavy duty four-way shuttle car makes the left and right warehouses communicate with each other. The advanced modern logistics equipment used in the warehouse area, including 6 units four-way shuttle systems, 4 sets of vertical lifting systems, conveyor systems and logistics management systems (WMS), is committed to building the warehouse into an information and automation Integrated intelligent warehouse .

Heavy duty four-way shuttle storage system

The four-way shuttle is an intelligent device for handling pallet goods. It can realize both vertical and horizontal walking, and it can reach any position in the warehouse. The horizontal movement and storage operations of goods in the racking system are only completed by a four-way shuttle car. Through the elevator to change levels, the system automation is greatly improved.

The four-way shuttle automated storage system can be considered as a new storage concept based on the shuttle rack system.

The four-way shuttle has significant characteristics:

1)The four-way shuttle is compact in structure, small in height and size, and saves more storage space; not only can it travel four-way on the supporting rail , but also can use the vertical elevator to realize the level change operation, further increase the flexibility and scalability of the warehouse racking layout and pallet four-way shuttle operations;

2)Four-way running : It can be driven along the vertical or horizontal rails to achieve one-stop point-to-point transportation, which can reach any cargo position on the plane level of the warehouse;

3)Intelligent level change: the four-way shuttle can realize the efficient working method of automatic and accurate level change through the elevator ; realize three-dimensional space movement, and accurately control the entry and exit of each cargo space in the racking area;

4)Intelligent control: It has two working modes: fully automatic and semi-automatic. Greatly improve the efficiency of cargo access and space utilization of the warehouse. The use of WMS, WCS system software and enterprise ERP / SAP / MES and other management system software can also maintain the first-in first-out storage of goods, eliminating the chaotic disorder or low efficiency of operations caused by human factors;

5)High storage space utilization rate: The storage density of traditional warehouses is low, resulting in low utilization of the total area of the warehouse and low utilization of the warehouse volume; the four-way shuttle runs on the main rails in the racking in four directions without forklifts and other equipment coordinated, the operation can be completed independently. Since the volume of the main rail of the rack is smaller than the volume of the forklift's working channel, the four-way shuttle-type automated dense storage system can further improve the storage space utilization rate compared to the ordinary shuttle car rack system. Increased by 20% to 30%, which is 2 to 5 times that of ordinary flat storage;

6)Dynamic management of cargo space: The traditional warehouse is just a place for cargo storage, and the only function of storing cargo is a 'static storage'. The four-way shuttle is used as an advanced automated material handling equipment, which not only keeps the cargo in full information automatic access in the warehouse as needed, and can be organically connected with production links outside the warehouse. It is easy to form an advanced logistics system and improve the level of enterprise management;

7)Unmanned automatic storage mode: greatly reduce the workload of warehouse staff, and provide the possibility for the warehouse to realize unmanned work. The goods exit the three-dimensional warehouse directly by the pallet four-way shuttle, vertical elevator and automatic conveyor. The warehouse staff only need to monitor the operation of the system from time to time, realizing the access automation, without the need for personnel to enter the warehouse to perform operations, especially suitable for cold storage, storage of toxic goods and other warehouses that are not suitable for long-term residence of personnel, is the future of high-density dense storage and the development direction of automated warehousing.

Features of four-way shuttle

○ Independent integrated circuit board technology

○ Unique communication technology

○ Run in four directions and work across support rails

○ Unique design, level change operation

○ Multi-vehicle collaboration on the same floor

○ Assist in intelligent scheduling and path planning

○ Fleet operations are not limited to the first-in first-out (FIFO) or first-in-first-out (FILO) storage operations

1. High intensive level, the inventory rate rises by 20% ~ 30% compared with the same ordinary warehouse;

2. High degree of automation, four-way shuttle + elevator + WCS / WMS management system, docking with customer NCC, to realize automatic entry and exit;

3. The overall system is highly flexible and is reflected in two aspects:

A. The two left and right warehouses are connected, and each set of four-way shuttle and elevator have mutual replacement. If a single system fails, you can call the other three systems at any time to achieve normal work in the warehouse;

B. The number of four-way shuttles can be increased at any time according to customer efficiency requirements.

In recent years, the four-way shuttle is widely used in the logistics and storage industry. Nanjing Inform will, as always, strive to keep up with customer needs, tailor-made logistics integration solutions for it, use advanced science and technology, optimize indoor warehousing supply and circulation links, and help customers realize value-added throughout the supply chain. Sustainable development provides guarantees and makes logistics warehousing more intelligent.