1. Customer introduction

A multi shuttle system project located in South Korea.

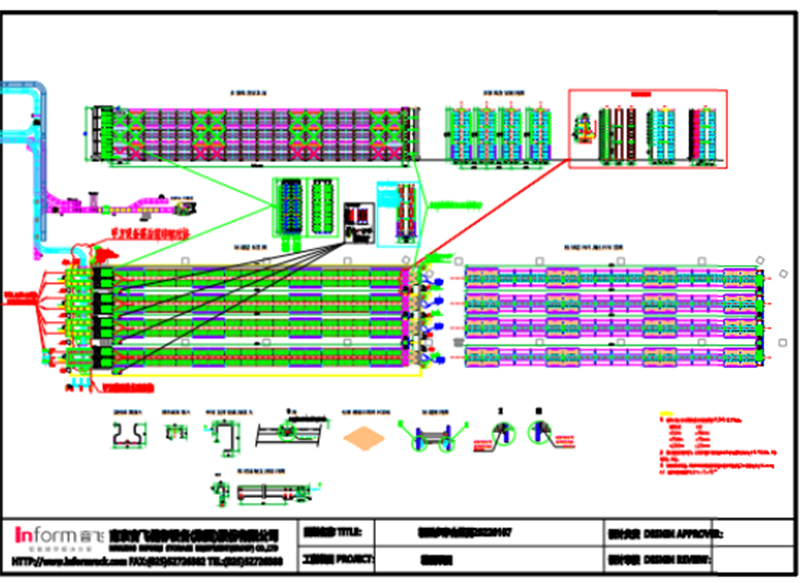

2.Project overview

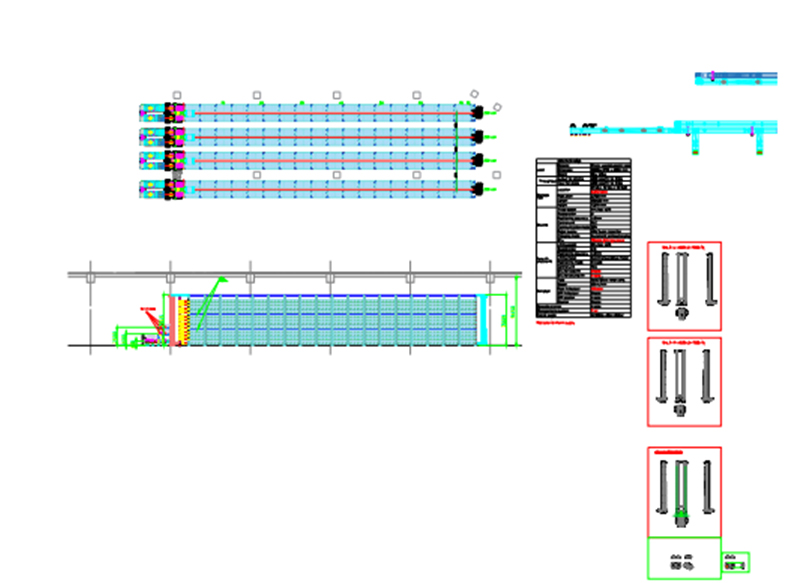

- The size of the bin is 600 * 400 * 280mm

- 30kg

- 6912 bins in total

- 18 multi shuttles

- 4 small shuttle level changing lifters

- 8 bin lifters

Layout

3.Project features

1). High self-production rate: All major core equipment of the system are self-produced, and the self-production rate exceeds 95%;

2). The self-developed multi shuttle has excellent performance and uses super capacitors as power sources;

3).Independently developed and customized a powerful WMS and WCS system for the company:

☆ The WMS system focuses on order classification management and task distribution;

☆ The WCS system focuses on:

① Task scheduling, charging management, fault feedback, operation status information collection and analysis of all shuttle vehicles, etc.;

②Scheduling of lifter pick-up and drop-off tasks and level-changing tasks;

4. Project benefits

1). Reduce customer investment risk

2). Improve the efficiency of logistics automation equipment

3). Reduce warehousing and logistics operating costs

5. One of the operation modes of Inform Storage

1) Operation services for this type of project:

Provide customers with a complete set of service solutions such as warehousing design and planning, intelligent warehousing and storage, handling equipment (racking + robots), warehousing picking equipment, conveying and sorting equipment, operation management services and warehouse management software:

2) Inbound quality inspection:

a. Jointly formulate quality inspection standards with merchants;

b. Configure information-based testing equipment to ensure that quality inspection results can be tracked and recorded;

c. It can also be adopted as the way of merchants dispatching quality inspection personnel

3) Goods storage:

a. Sort out the customer's business model and determine the storage plan;

b. Configure appropriate storage equipment according to the characteristics of the stored goods;

c. Inventory dynamic management to realize real-time docking of goods information and merchants

4) Goods in and out of warehouse:

a. Configure optimized in-out automation equipment according to the characteristics of customer orders;

b. Configure appropriate WMS to connect with the customer's order management system according to the characteristics of the technological process;

c. According to the quality requirements of warehousing services (accuracy rate of receipt and delivery, Inventory accuracy rate, product breakage rate) configure emergency plans

5) Order picking:

Configure optimized goods-to-person picking solutions based on order characteristics.

NanJing Inform Storage Equipment (Group) Co.,Ltd

Mobile phone: +8613636391926

Address: No. 470, Yinhua Street, Jiangning District,Nanjing Ctiy,China 211102

Website: www.informrack.com

Email: lhm@informrack.com