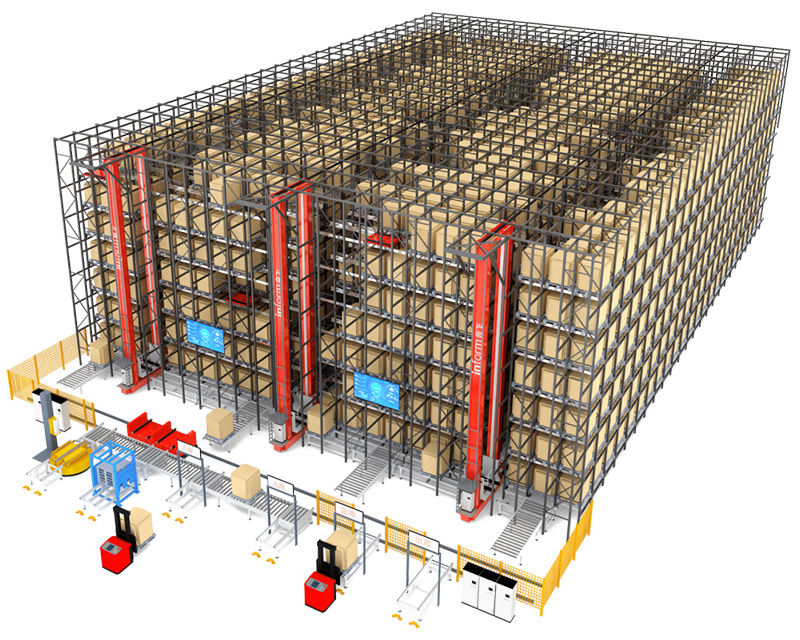

The Inform Storage two-way radio shuttle + stacker crane system has played an important role in automated warehousing systems. Through advanced equipment and intelligent management methods, it improves the efficiency and space utilization of warehousing.

The automated warehouse system consists of a two-way radio shuttle, a stacker crane, and a loading platform with lifting function. The shuttle is used to move horizontally between rackngs, while the stacker crane is used to move vertically, achieving fast access and handling of pallet goods. This automated warehouse solution has the characteristics of high dynamics, high density, and space saving, which can meet the warehousing needs of different industries.

The application of the Inform storage two-way radio shuttle + stacker crane system is very extensive and has been successfully applied in multiple industries and projects. Its performance is stable, ensuring the efficient operation of warehousing operations, and continuously integrating digital technology for software and hardware equipment iteration and upgrading, enhancing the intelligence level of the system.

In the inbound warehousing process, the products to be stored are transported to the automated warehouse through the conveyor line. The stacker crane takes the pallets according to the instructions and places them at the end of the aisle allocated by the WMS software. Then, the shuttle stores the goods at the designated location. The outbound process involves the shuttle moving the designated goods to the sub aisle port, the stacker crane picking up the goods through forks, placing them on the outbound conveyor line, and then being picked up and shipped by forklifts or other handling equipment. This process is both efficient and flexible, and can meet the needs of different warehousing scenarios.

The Inform Storage two-way radio shuttle + stacker crane system has mature application and stable performance. It can improve storage efficiency and space utilization, and reduce operating costs. With the continuous development of intelligent warehousing technology, this solution will be applied and promoted in more industries.

1. System advantages

1) High storage density and high warehouse utilization: Through the collaborative work of shuttles and stacker cranes, the warehouse utilization and storage density can be improved by 30% compared to traditional aisle stacker crane warehouses.

2) Low overall investment cost: This plan has high cost-effectiveness and helps to reduce overall investment costs.

3) Flexible planning: The design of the radio shuttle allows for an increase in the depth of the roadway, providing multiple optional system layout options.

4) Realize unmanned warehouse operations: Through WMS management and WCS scheduling, achieve unmanned warehouse operations, improve efficiency and accuracy. Automatic data backup ensures consistency between accounts and assets.

2. Problems

Application scenarios for warehouse operations with small warehouse area, low space utilization, and high picking efficiency requirements

3. Efficiency value

Compared with traditional pallet rackings and mobile rackings, this automated warehouse system provides 100% channel storage capacity, greatly improving storage efficiency and space utilization.

4. Application scenarios

1) A large number of palletized goods require large-scale inbound and outbound operations

2) Batch caching of temporary storage orders for palletized goods

3) High storage capacity and periodic large in/out of goods

5. Applicable industries

Cold chain, 3C, retail, pharmaceuticals......

NanJing Inform Storage Equipment (Group) Co.,Ltd

Mobile phone: +8613636391926

Address: No. 470, Yinhua Street, Jiangning District,Nanjing Ctiy,China 211102

Website: www.informrack.com

Email: lhm@informrack.com