Short Description

Carton flow racking, equipped with slight inclined roller, allows carton to flow from higher loading side to lower retrieval side. It saves warehouse space by eliminating walkways and increases picking speeds and productivity.

Product Details

Racking Components:

Product Analysis:

Racking type: | Carton flow racking |

Material: | Q235/Q355 Steel | Certificate | CE, ISO |

Size: | customized | Loading: | 100-1000kg/level |

Surface treatment: | powder coating/galvanized | Color: | RAL color code |

Pitch | 50mm | Place of origin | Nanjing, China |

Application: | supermarket, pharmaceutical, chemical and electronics industries |

① Working Principle

The working principle of carton flow racking is similar to gravity racking, the main difference is that gravity racking is for pallet moving, while carton flow racking is for carton or box/bin moving. Cartons are flowed from one side, and retrieved from the other.

◆Accessory: With a picking station in front of racking, it's easier for operator to dispense carton or box/bin.

◆Accessory: With round tube divider between roller, each box at horizontal direction can be divided to avoid collision. It's quite necessary for battery storage.

② FIFO racking type

This system uses a combination of rails and Wheels. The rails are built on a slight incline, higher on the side that is flowed, so that the cartons move forward when they are loaded into the system. Cartons of identical products are loaded in one behind the other. The carton flows forward under gravity to create a strict 'First In ,First Out' moving rotation.

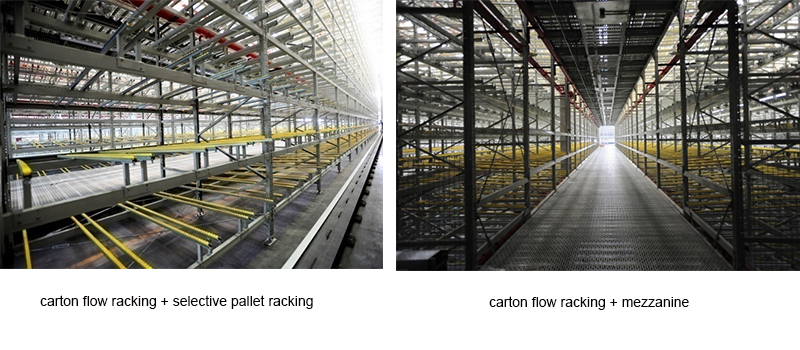

③ Adaptability with other racking

Carton Flow racking can be integrated with other racking types to create more storage modes. For example, carton flow racking + selective pallet racking; carton flow racking + mezzanine.

④Advantages

Carton Flow dynamic storage system offers many advantages in the order picking process.

• Reducing walking

• Saving space by eliminating walkways

• Improving picking speeds and productivity

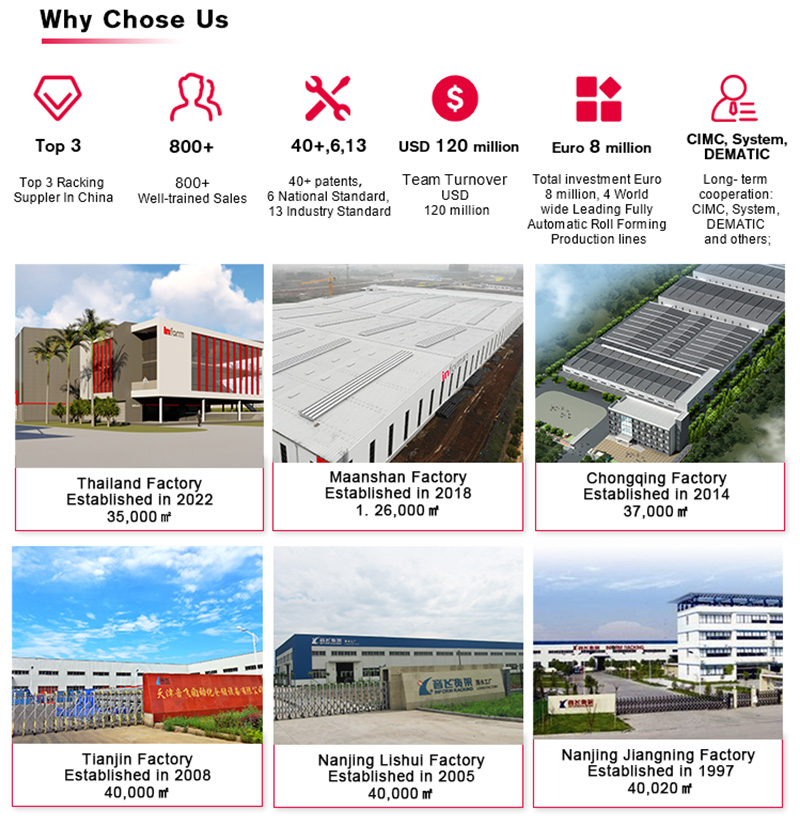

Why choose us?

Top 3 Racking Suppler In China

The Only One A-share Listed Racking Manufacturer

1. NanJing Inform Storage Equipment Group,as a public listed state controlled enterprise, specialized in the logistic storage solution field since 1997.( 27 years of experience)

2.Core Business: Racking

Strategic Business:Automatic System Integration

Growing Business: Warehouse Operation Service

3.Inform owns 6 factories, with over 1000 employees. Inform listed A-share on June 11, 2015, stock code: 603066, becoming the first listed company in China’s warehousing industry.

Q1: What’s your trading terms?

1) Payment terms: As general, T/T 30% deposit after order confirmed, 70% balance paid against BL. L/C also available.

2) Shipping port: Shanghai / Nanjing port China.

3) Discounts: we will offer the biggest discount for large quantity.

Q2: Are you a factory or trading company?

A:We are factory and have 5 factories.We’ve been in the market of logistic storage solutionssince 1997.We design,manufacture racking and assemble shuttle, four-way shuttle etc by ourselves.

Q3: Do you have OEM products to sell?

A:Yes.Both OEM and ODM are available .

Q4:Do you have the minimum order requirements?

A:Any quantity and customized design is acceptable.

Q5:Are samples available?

A:Yes. Short sections of samples can be provided for free, but the international transportation will be at the customers’ expense.

Q6:What’s the delivery time?

A:It depends on the order quantity and racking types. Generally speaking, for the standard pallet racking, it will be within 20 days.